Electric motors are the backbone of countless industries, powering everything from pumps and fans to conveyor belts and production lines. Over time, these motors are exposed to harsh operating conditions—dust, heat, moisture, and chemical contaminants—that can compromise their efficiency and reliability. One of the most critical yet often overlooked steps in maintaining and repairing electric motors is varnishing the windings. At Gibbons Engineering Group, we pride ourselves on offering a comprehensive rewinds and repairs service, including professional varnishing that prolongs the life of your motor and ensures peak performance.

Why Varnishing Matters

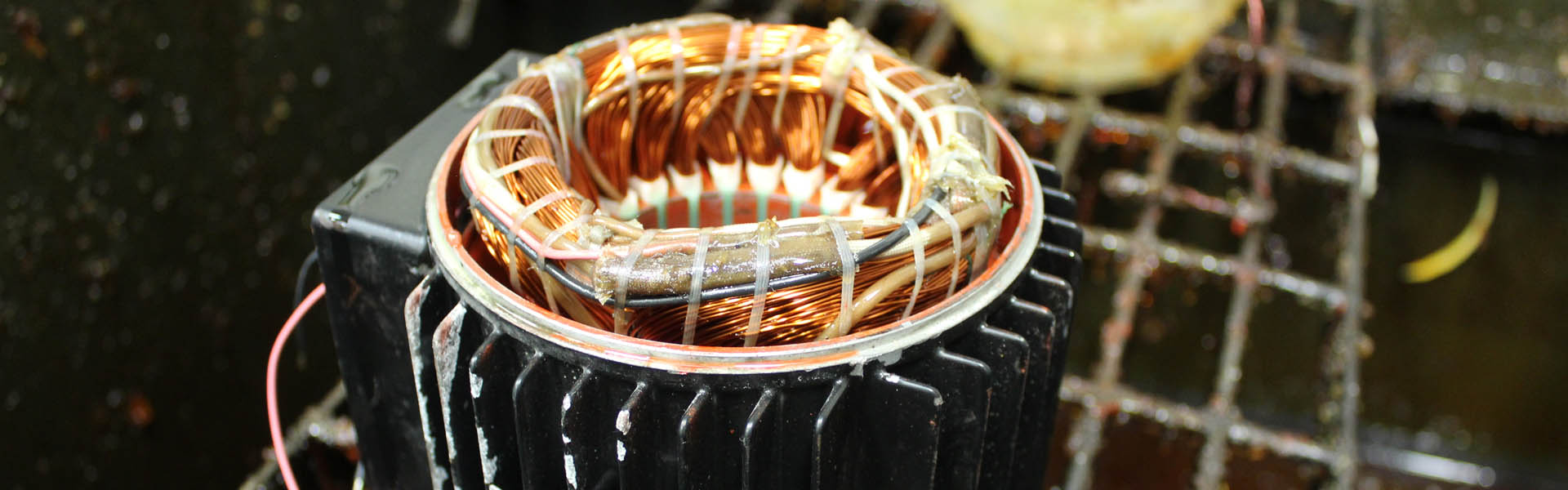

Varnishing serves as a protective shield for the motor windings, which are typically made of copper or aluminium wire wound into tight coils. These windings are essential for generating the magnetic field that powers the motor. However, without proper insulation and protection, they are vulnerable to moisture ingress, dust, oil, and other contaminants. Varnish provides electrical insulation, preventing short circuits, and helps to dissipate heat generated during operation. It also reinforces mechanical strength, ensuring the windings remain secure even under heavy vibration.

How We Do It

At Gibbons Engineering Group, our rewinds and repairs team follows a meticulous process to ensure the best results. After carefully rewinding the motor windings to manufacturer specifications, we apply high-quality insulating varnish using either the dip-and-bake or trickle method, depending on the motor’s design and application.

-

Dip-and-bake: We immerse the windings in varnish, ensuring complete coverage. Excess varnish is removed before the windings are baked in an oven at the correct temperature, allowing the varnish to cure and form a durable protective layer.

-

Trickle varnishing: For certain applications, we use a controlled varnish application while the motor rotates slowly. This technique ensures even distribution and penetration of the varnish.

Both methods meet or exceed industry standards, ensuring that every repaired or refurbished motor leaves our workshop fully protected and ready for reliable service.

Watch our YouTube video below to understand the process of varnishing an electric motor. Proper varnishing is not just an add-on—it’s a crucial step that enhances the lifespan and performance of electric motors. By choosing Gibbons Engineering Group for your motor rewinds and repairs, you’re investing in quality, reliability, and peace of mind. Contact us today to learn more about our comprehensive repair services and how we can keep your motors running smoothly.