Project Description

Location: Cargo Tunnel – South and North Plant Rooms

Service: Routine Maintenance of Supply & Extract Fans

Date: 16/07/2025

Overview

Gibbons Engineering Group was contracted to carry out scheduled maintenance on the ventilation systems serving the cargo tunnel at a UK Airport. The work was focused on both supply and extract fans located in the North and South plant rooms.

Scope of Work

Our engineers performed a thorough maintenance procedure which included:

-

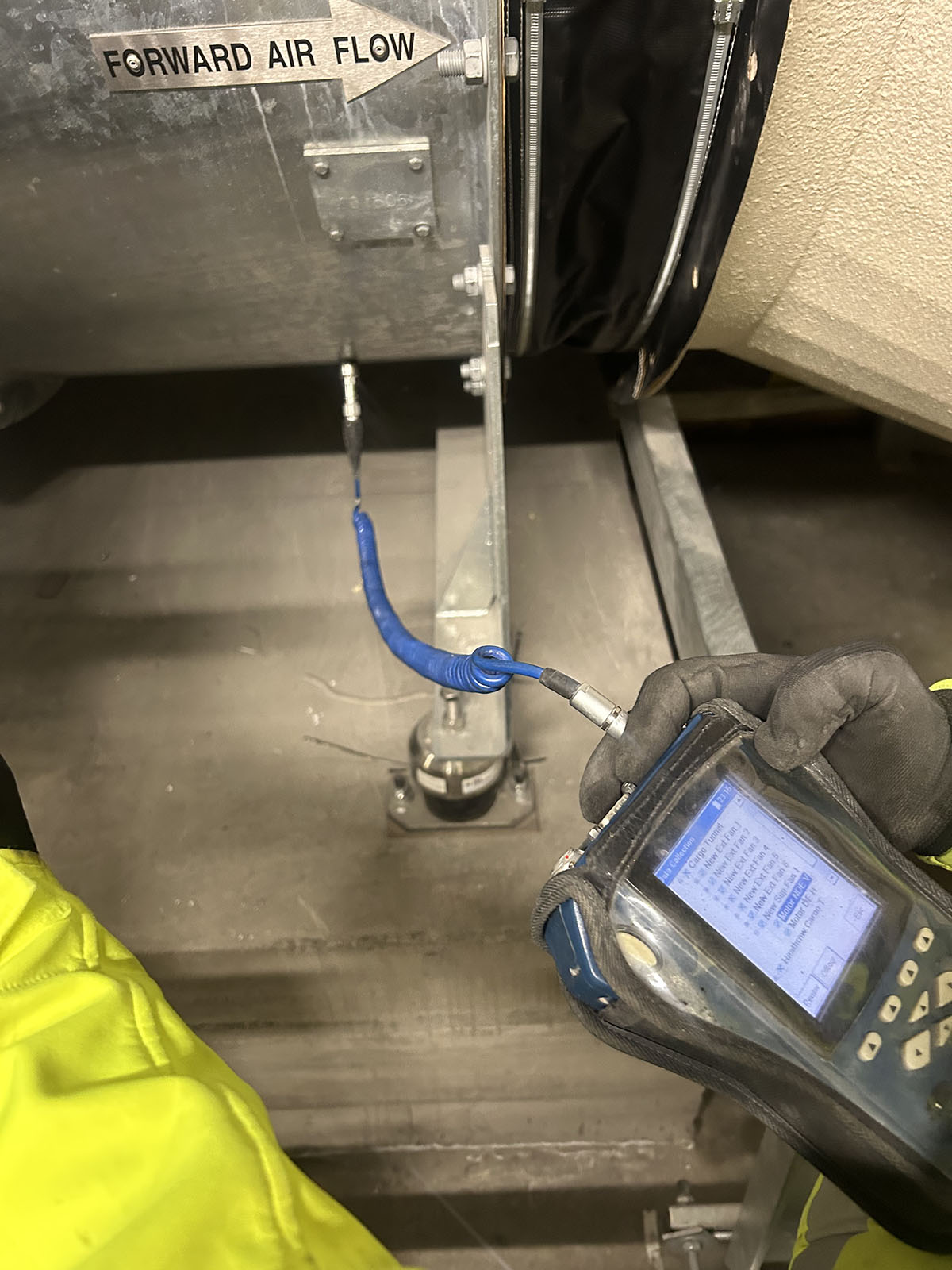

Greasing of fan bearings to ensure smooth mechanical performance

-

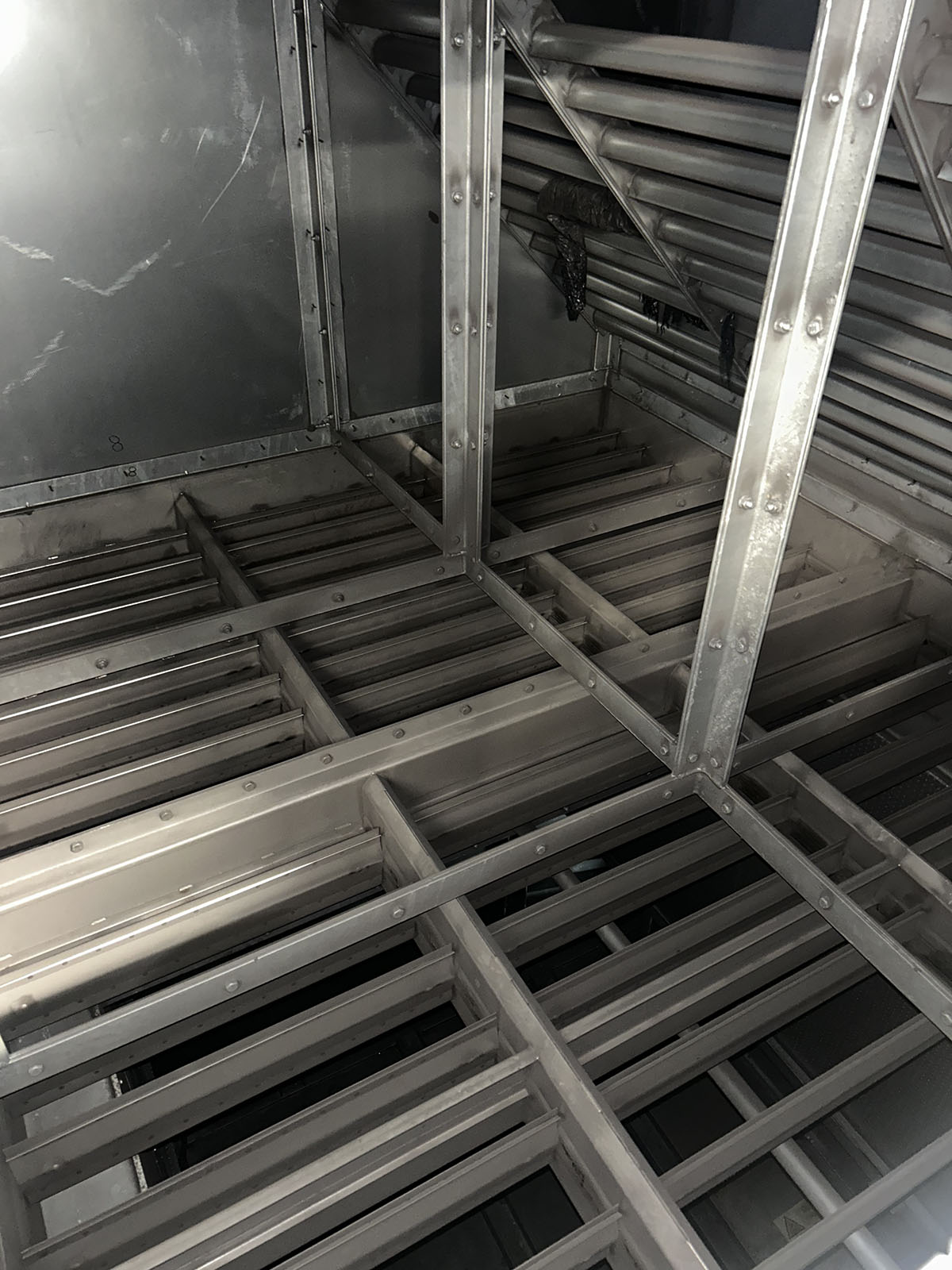

Visual inspections of:

-

Anti-vibration (AV) mounts

-

Flexible connectors

-

Motor and impeller (accessed via hatches)

-

-

Operational checks on the damper systems to confirm full range of movement

-

Performance testing with each fan run at full speed to record:

-

Vibration readings (provided in a separate detailed report)

-

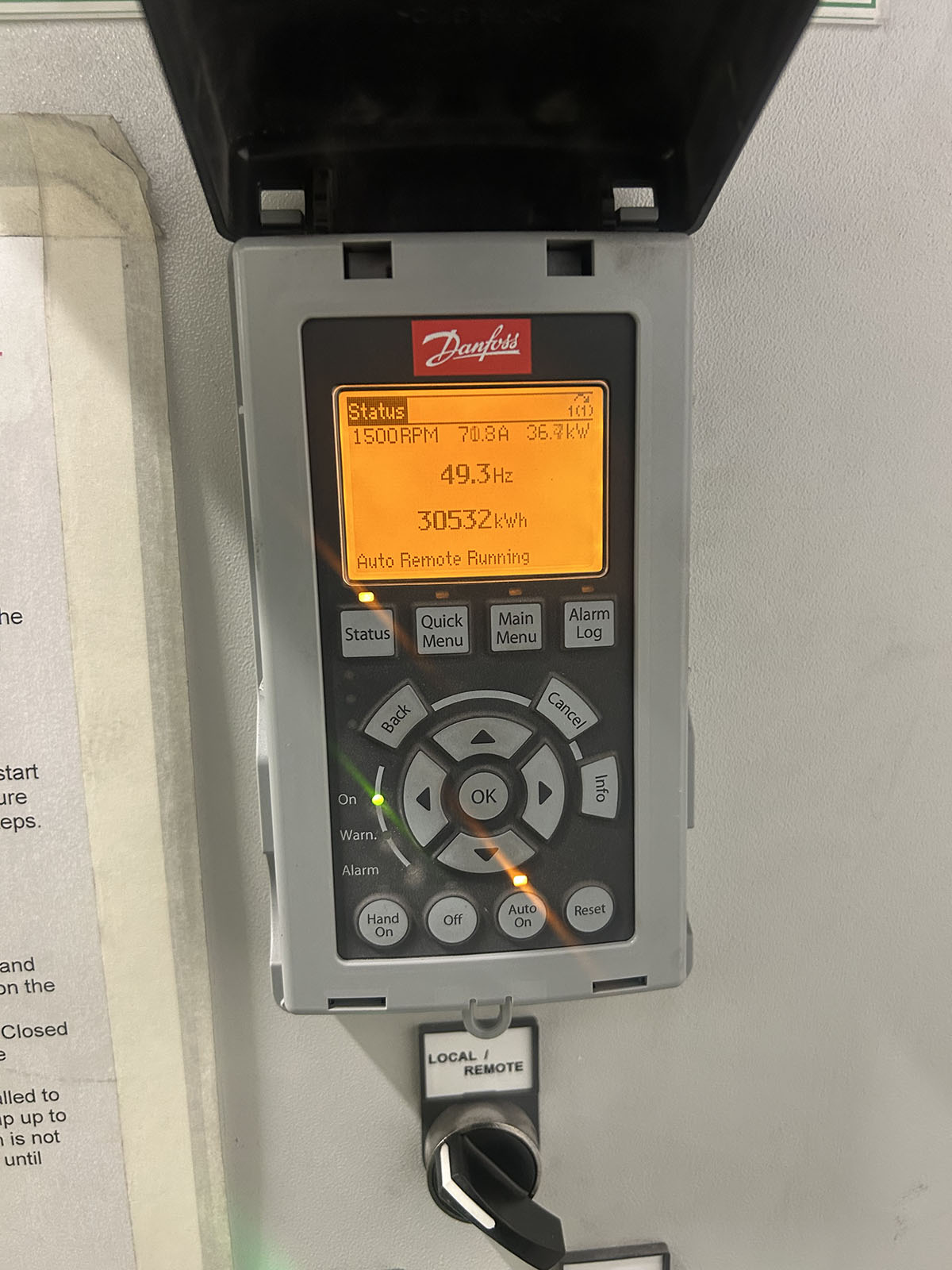

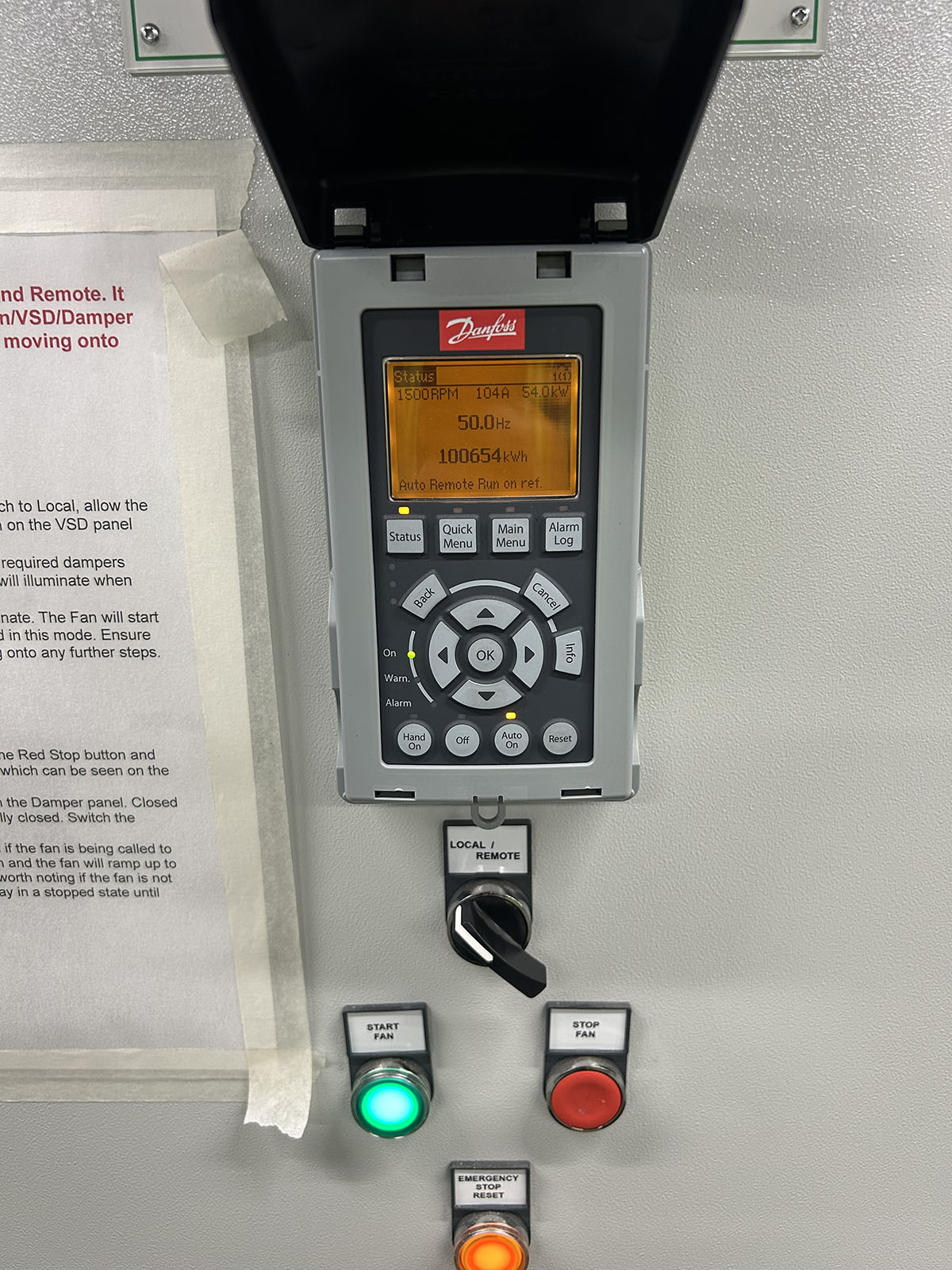

Running current (Amps) from the Variable Speed Drives (VSDs)

-

Recorded Running Amps

South Plant Room:

-

Supply Fan 1 – N/A

-

Supply Fan 2 – 94.1A @ 49Hz

-

Extract Fan 1 – 103A @ 50Hz

-

Extract Fan 2 – 108A @ 50Hz

-

Extract Fan 3 – 104A @ 50Hz

North Plant Room:

-

Extract Fan 1 – N/A

-

Extract Fan 2 – 70.2A @ 49.3Hz

-

Extract Fan 3 – 71A @ 49.3Hz

Outcome

The fans, all of which are newly installed, were found to be operating within optimal parameters. No defects or performance issues were identified. Bearings were successfully lubricated and will require re-greasing in 12 months’ time as part of the ongoing preventative maintenance schedule.

This routine inspection and service ensures continued reliability and efficiency of the critical ventilation infrastructure within the cargo tunnel. It also contributes to the Airport’s commitment to high standards in safety and operational uptime.